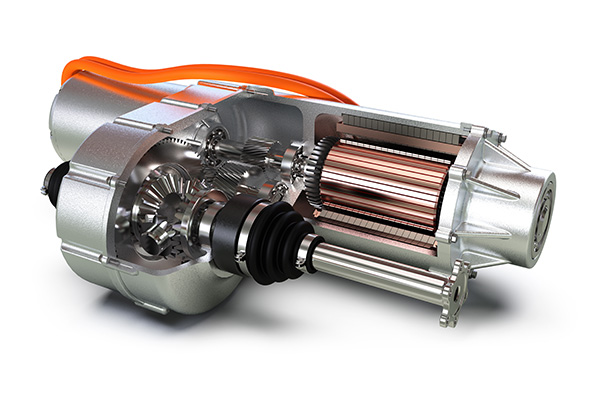

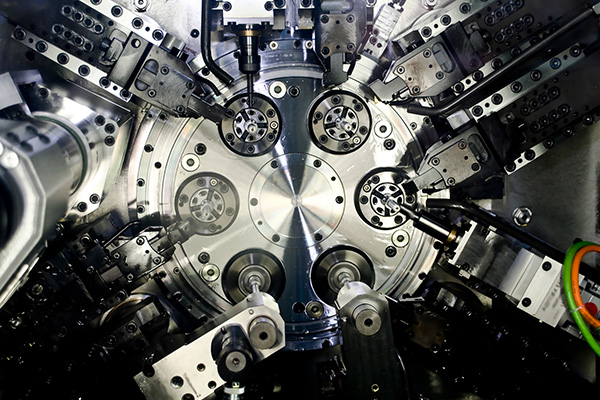

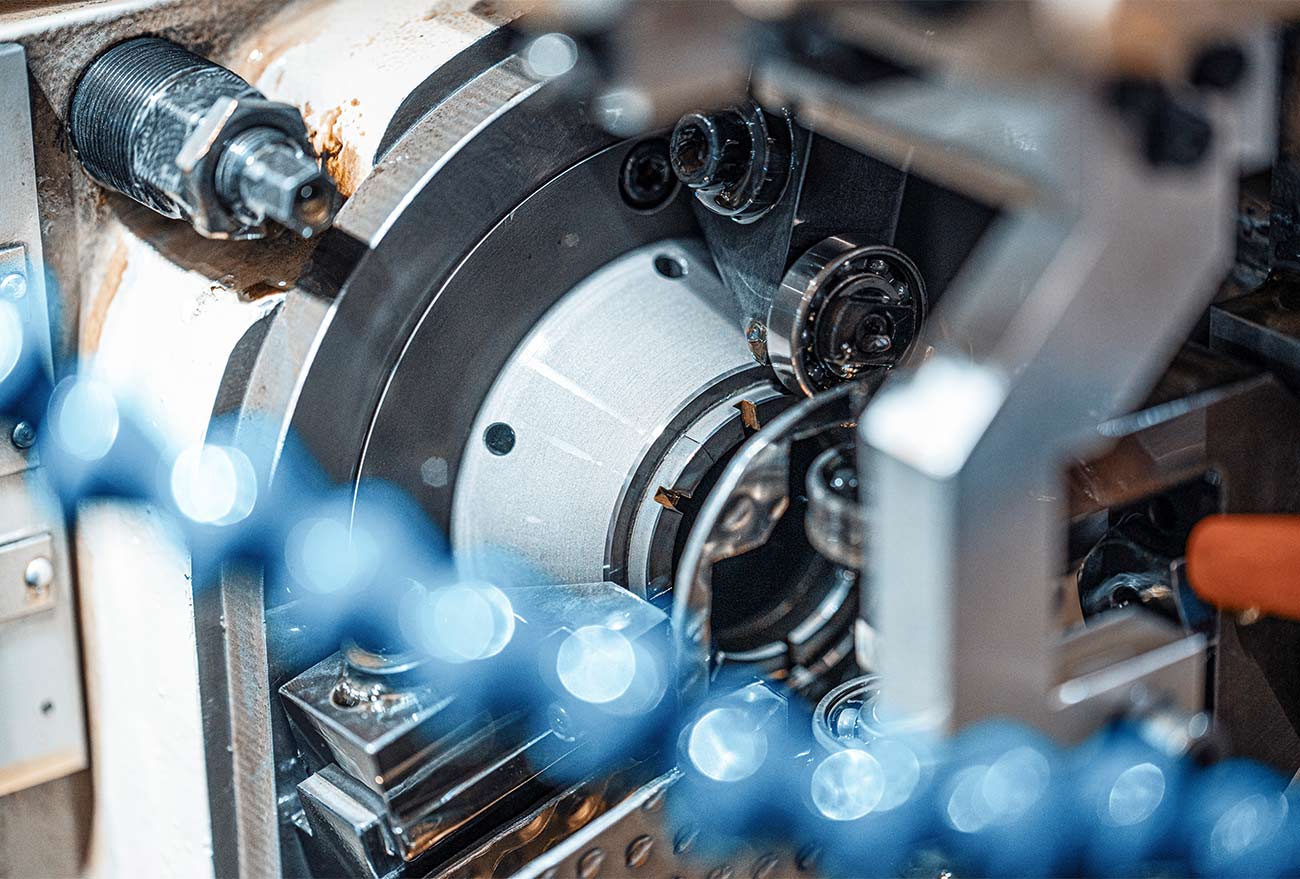

Unser Portfolio umfasst Wälzlager verschiedenster Bauformen für den Einsatz in unterschiedlichen Branchen – von 32 bis 1.600 mm Außendurchmesserbereich.

Lebensmittel- & Getränkeindustrie

An Wälzlager in der Lebensmittel- und Getränkeindustrie werden besondere Ansprüche gestellt. Oft müssen diese aggressiven Umgebungsbedingungen und langwierigen Reinigungsprozessen standhalten.

Details